Continuous

Filtration / Drying

Continuous filtration is available in evaluation, pilot, production scale platforms

Lower footprint - One complete plant replaces a traditional 2 to 3 floor batch production facility.

Astro DecFilterDryer

a game-changing new filtration solution available for both pilot and production scale operations

-

High Capacity: Process up to 100 kg per hour, with an impressive capability of 750,000 kg per year (operating 300 days at 24 hours)

-

Proven Technology: Utilizes well-established Nutsche Filtration for reliable performance

-

Efficiency Boost: Processes thin cakes to significantly reduce filtration time and allows for efficient washing, minimizing solvent usage

-

Automation Ready: Features automated WIP/SIP management

Pilot Scale

-

Zero Product Loss: The innovative inverted discharge method ensures no product heel, maximizing yield

-

Swift Changeovers: Experience faster product changeovers to keep your production line agile

-

Flexible Integration: Can easily interface with both batch and continuous systems

-

Safety First: Available in both Non-ATEX and ATEX versions to meet diverse operational needs

-

Compact Solution: Also offers a single-stage version for smaller operations at 10kg per hour

Production Scale

Our unique internationally patented Continuous Carousel Filtration or 'Flow Chemistry' systems are at the cutting edge of modern chemistry technology. They are designed to enhance your key protocols and efficiencies in Fine Chemical, Pharmaceutical and Laboratory processing.

Continuous Filter Dryer systems automatically filter, wash, dry and discharge solids in a continuous manner. The versatility of Continuous Filtration's ability to continually loop process smaller amounts of APIs in 3 to 4 minutes from slurry to dry cake with precise repeatability, yet still being able to produce larger quantity production scale throughput - makes it highly suitable for both APIs & HPAPIs. Continuous Filtration is a contained, safe and highly controlled way to process hazardous or valuable ingredients or HPAPIs highly potent active pharmaceutical ingredients.

Protocols

-

No mechanical agitation damage or crystal shear

-

Reliable consistency in cake filtration

-

Accurate repeatability of washing parameters

-

Atomisation nozzles dispense wash solvent preventing disturbance to the cake

-

Thinner cake height technology, typically 10 - 30 mm

-

Improved wash efficiency!

-

Local HMI or DCS control system allows for safe operation

-

Integrated alarm systems for automated continuous operation

Key Features

Lower footprint - A complete plant, replacing a traditional 2 to 3 floor batch production facility!

-

Very high repeatability and consistency in filtration

-

Reduced solvent usage, energy and waste

-

0.1 mm heel! Significantly lower heel – Significantly reducing product loss!

-

Entry to exit cycle time in minutes… not hours!

-

Filtration, washing and drying in just a few short runs!

-

Drying to <1% moisture content achieved within minutes

-

Typical throughputs of 1kg per hour to 24kg per hour of dried product

Validateable Technology

-

Successful industrial product trials carried out with both UK Pharma and Fine Chemical

-

Multiple academic papers published using the AWL continuous filter dryer

-

Drying validated with drying kinetics model

-

Credible technology due to detailed independent empirical research

Industries Served - Products Processed

-

Generic Pharma - Micronized Paracetamol, Granular Paracetamol

-

Specialized APIs - Lovastatin

-

Food and Beverage - Glucose, Nutritional Supplements

-

Fine Chemicals - Antiseptic, Disinfectants, Potassium Tartrate, Sodium Bicarbonate

-

Inorganics

Our Continuous Filtration is Available in Evaluation, Pilot, Production and Commercial Scale platforms. Typically from 1kg per hour to 24kg per hour of dried product.

CCF 20 Table Top

Continuous Carousel Filter

Laboratory Evaluator

-

20mm / 5 ports

-

2.5 to 5 L/hr slurry

-

0.5 to 1.0 kg/hr solids

-

Essential table-top lab equipment for evaluating filtration and washing processes

CCF 20 Lab-Scale Continuous

Carousel Filter

Evaluator Lite Version

-

20mm / 5 ports

-

1.5 to 3.0 L/hr slurry

-

0.3 to 0.6 kg/hr solids

CCF 50 Continuous Carousel Filter

Pilot & Production Scale

-

50mm / 5 ports

-

10 to 20 L/hr slurry

-

2.0 to 4.0 kg/hr filtered solids

-

Continuous automatic filtering and washing for your pilot/production scale process

-

ATEX options available

CCFD 50 Continuous Carousel Filter Dryer

Pilot/Production Scale

-

50 mm / 10 ports

-

10 to 20 L/hr slurry

-

2.0 to 4.0 kg/hr filtered solids

-

Continuous automatic filtering, washing and heated nitrogen/air drying for your pilot/production scale process

CCFD 20/50 Continuous Carousel Filter Dryer

Pilot & Production Scale

-

20 or 50 mm / 10 ports

-

10 to 20 L/hr slurry

-

2.0 to 4.0 kg/hr dry solids

-

Continuous automatic filtering, washing and drying

-

Vision system for fine control over filtration and washing processes

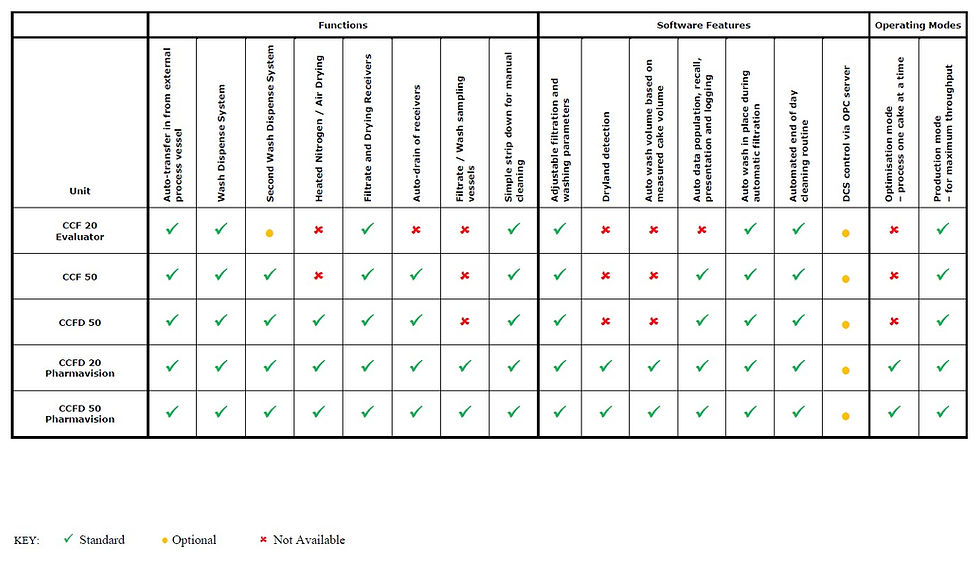

Continuous Carousel Filter Range Model Comparison